AM Enterprise 2022 Sample Reports

|

Manufacturing - Bill of Materials Listings

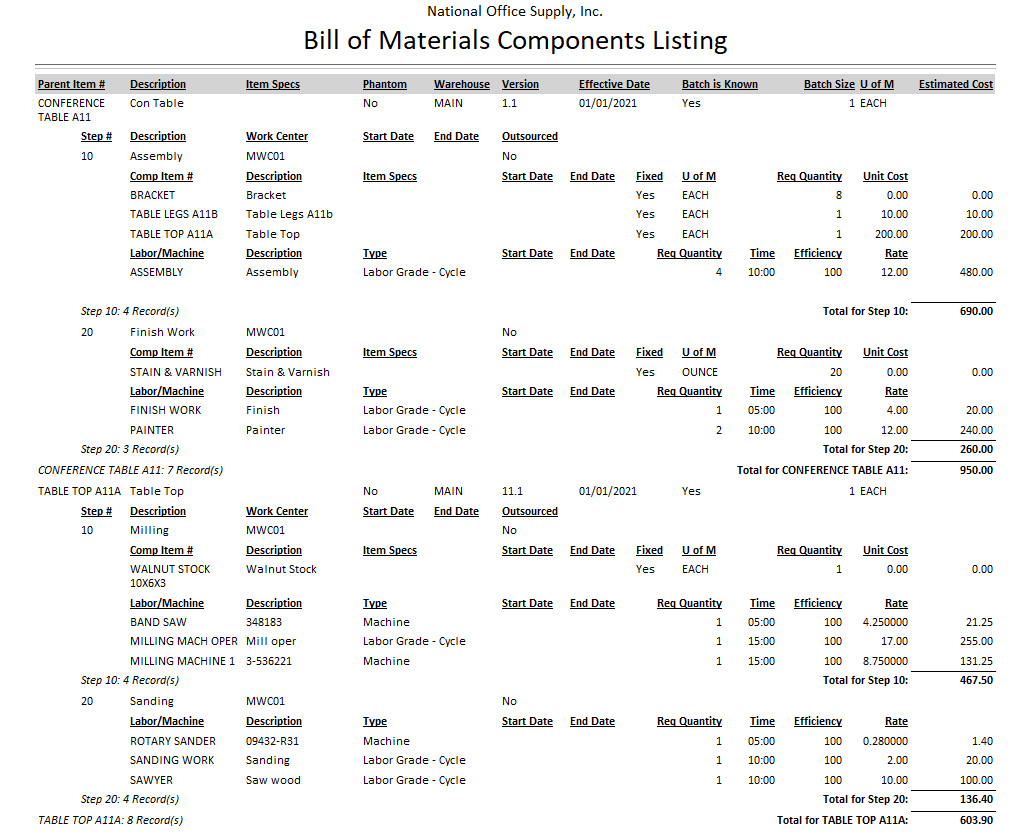

The Bill of Materials Listings is a set of reports that provide detailed information on bills of materials (BOM) recorded in AccountMate Enterprise. Each of the Bill of Materials Listings has various options and criteria that provide a variety of BOM-related information and report formats. Read the information below to get a closer look at each of the Bill of Materials Listings available in the Manufacturing module. Bill of Materials Components Listing The Bill of Materials Components Listing providesdetailed information about the settings and the components that make up a master item's bill of materials, whether it is for the current effective version or all versions of a master item's BOM. The report includes information such as the parent item number and description, inventory items, labor and machine resources at each manufacturing step level, version number and its effective date, and the estimated cost at each step. This report is handy in reviewing the components used in the manufacture of the parent items. You can choose to generate the report that includes only the inventory components, only

the labor components, only the machine components, or all components. You can elect to show in

the report only the parent item and its components or only phantom item and its components. The

report also provides the option to include only the BOM's current version in effect or all the

BOM versions set up for each master item. You can further opt to include in the report the

estimated overhead cost information.

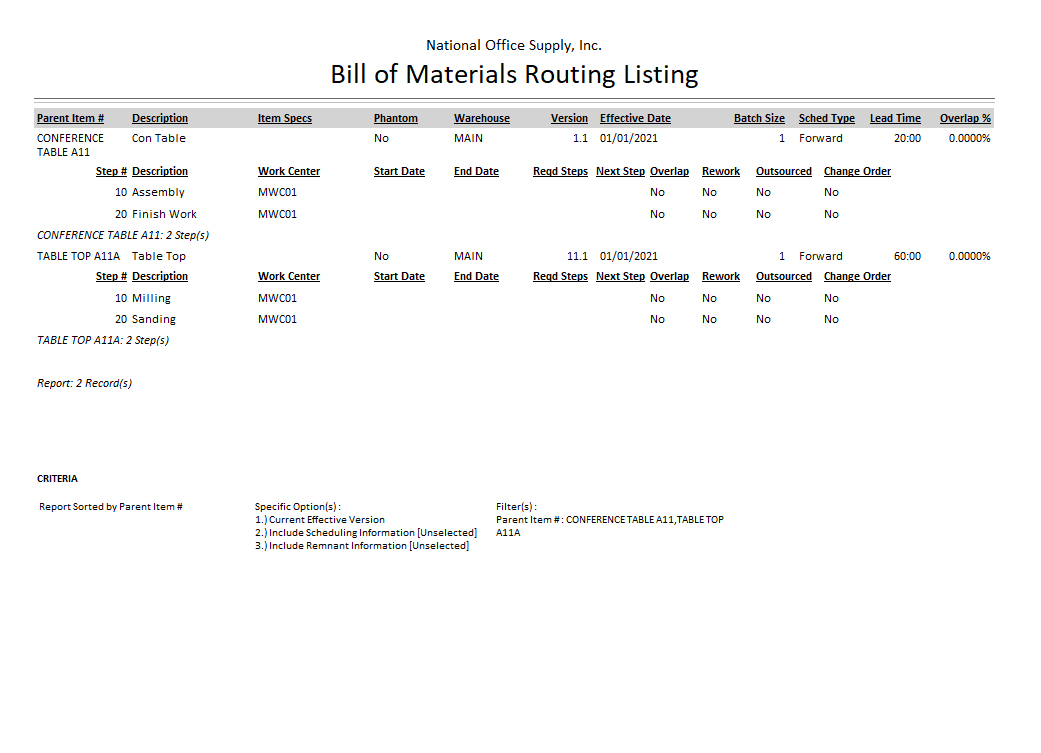

Bill of Materials Routing Listing The Bill of Materials Routing Listing provides detailed information on a bill of materials' routing steps in manufacturing. The report lists all the step levels and its description in a parent item's bill of materials as well as information on the work center assignment, start and end dates of each step, required steps (if any) prior to starting the step level, routing step overlap, scheduling and remnant information at each step level, if rework is allowed, and if routing step is outsourced to a third party. This report is useful in reviewing the routing steps involved for each parent item, and as reference in monitoring accuracy of manufacturing step levels. The report provides the option to include only the BOM's current effective version or all the

BOM versions set up for the master item. You can opt to include in the report the scheduling

information and remnant information.

|