AM Enterprise 2023 Sample Reports

|

Manufacturing - Production Reports

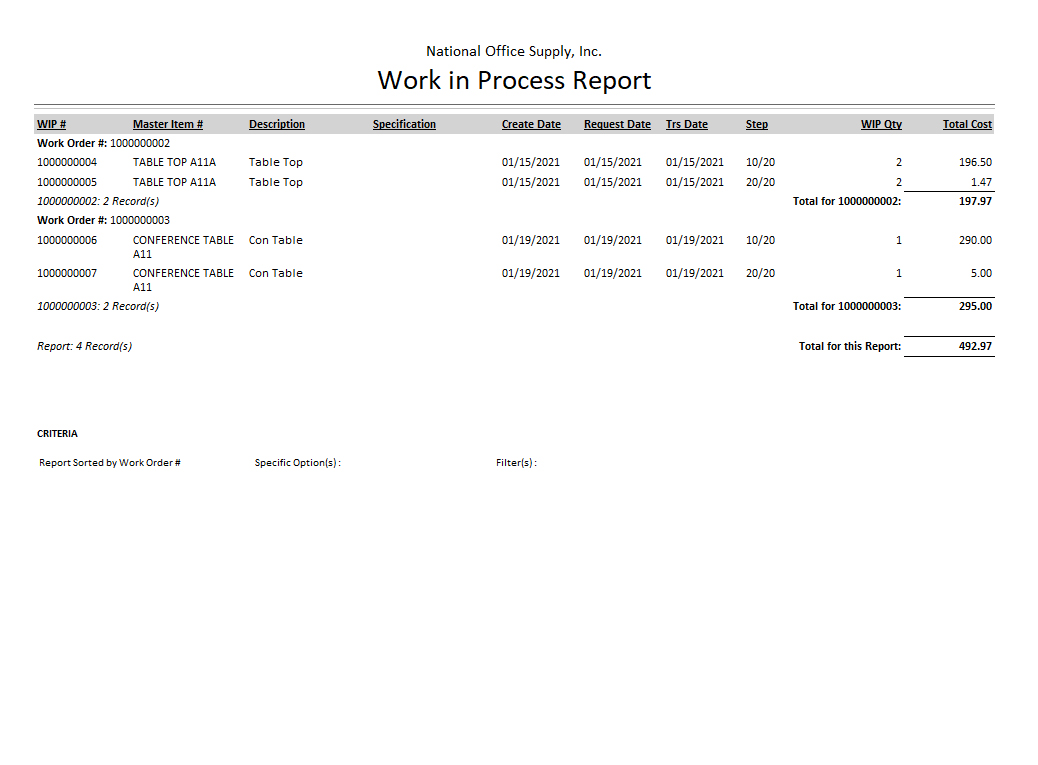

The Production Reports provide information that is important in planning and managing the inventory item, machine, and/or labor resources. More specifically, these reports provide information on the work orders that are still in process and the estimated quantities of component items and machine or labor resources to complete production. Each of the Production Reports has various options and criteria that provide a wide variety of work order production-related information and report formats. Read the information below to get a closer look at each of the Production Reports available in the Manufacturing module. Work in Process Report The Work in Process Report provides information on work orders that are recorded to

work-in-process. The specific information in this report includes the work order numbers, master

item numbers and descriptions, request date, transaction date, manufacturing step number,

work-in-process quantity, and total cost. This report serves as reference in identifying the

outstanding work orders and in monitoring the cost of the work orders posted to work-in-process.

It can also be useful in planning and managing the component resources availability.

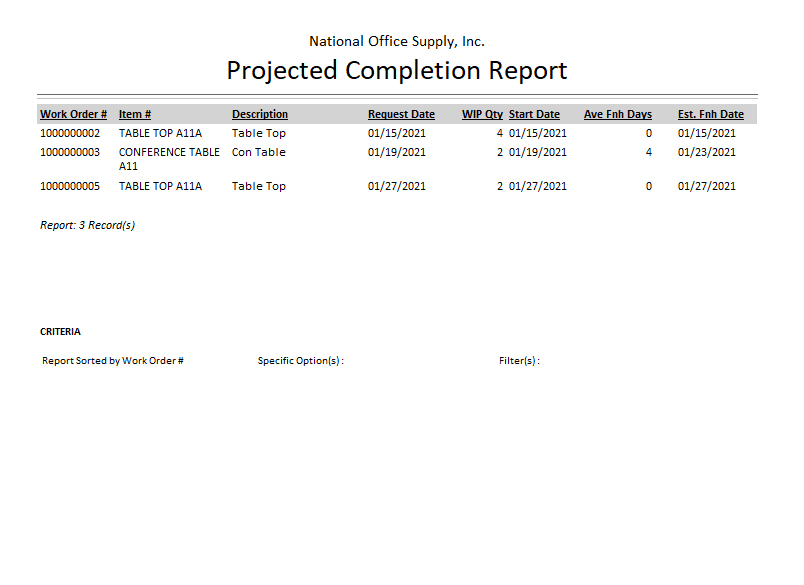

Projected Completion Report The Projected Completion Report provides information on the work-in-process transactions

that are posted in AccountMate but are not yet finished. The report includes details such as the

work order numbers, item numbers and descriptions, request dates, work-in-process quantities, start

dates, average number of days to finish each work order, and the estimated finished date. This

report comes in handy when you need to know the number of days it takes to complete the work orders

that are still in process, when you need to assign priority to the work orders for completion, and

when you plan the availability of resources needed to complete the work orders.

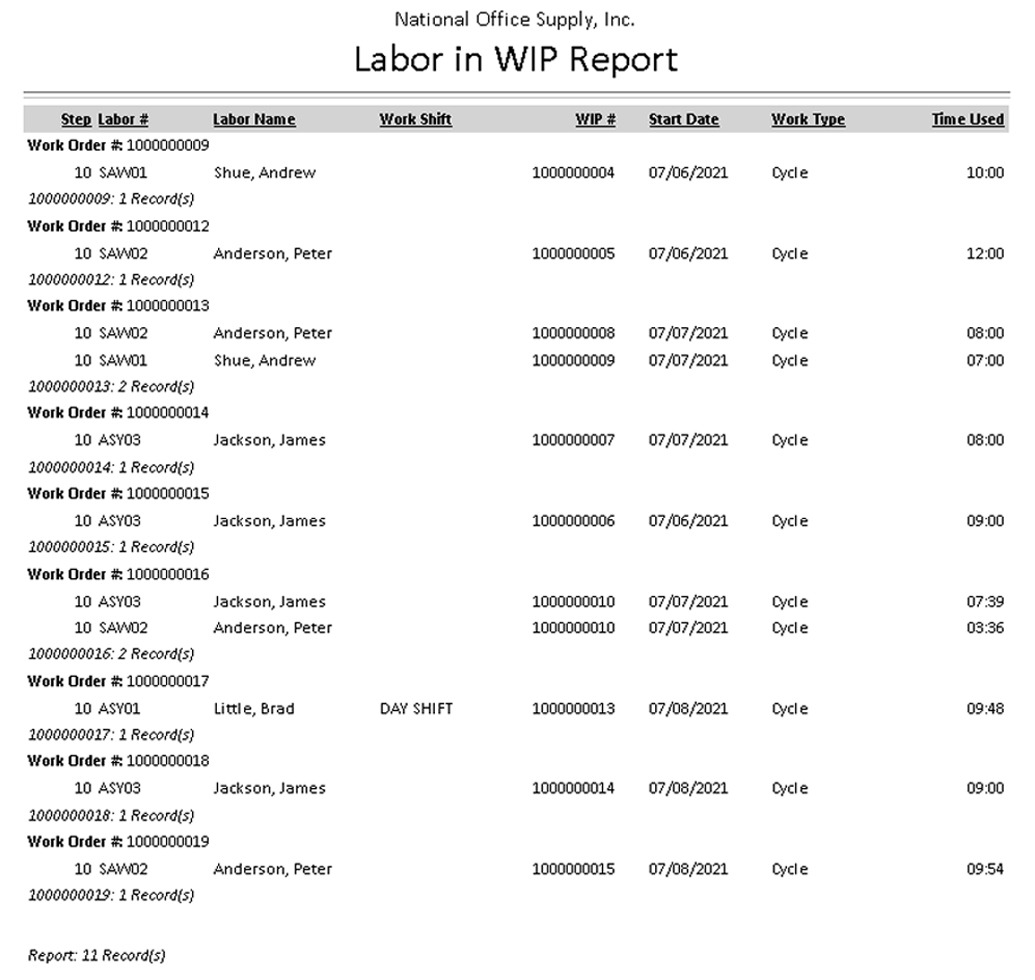

Labor in WIP Report The Labor in WIP Report provides information on the required manufacturing time of labor

components for each work order that is posted to work-in-process. This report displays information

such as work order numbers, manufacturing step levels, labor component numbers and names, start

dates, work shifts, work-in-process numbers, work types, and manufacturing time used. This report

is useful in reviewing and planning the labor resources schedule.

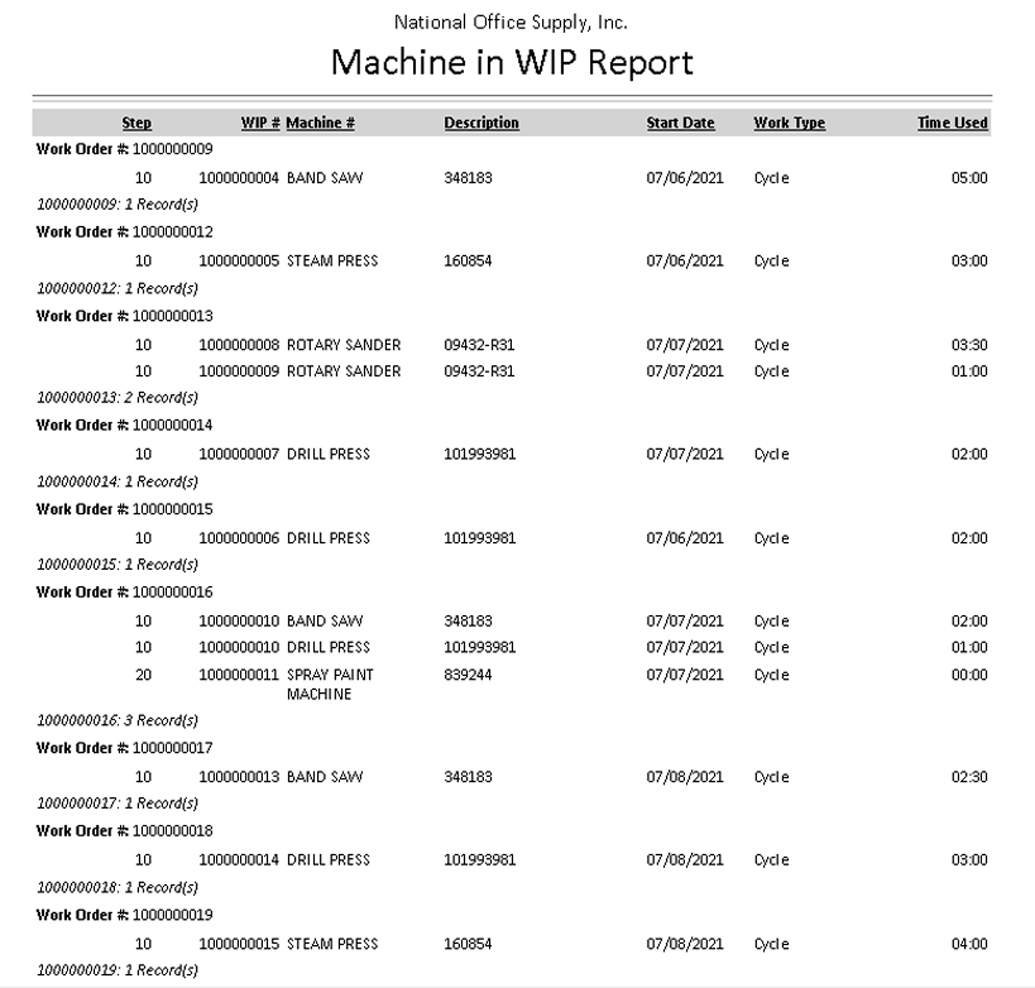

Machine in WIP Report The Machine in WIP Report provides information on the required manufacturing time of

machine components for each work order that is posted to work-in-process and when these machine

resources are needed. This report displays details such as work order numbers, work-in-process

numbers, manufacturing step levels, machine component numbers and descriptions, start dates,

work type, and manufacturing time used. This report is useful in reviewing and planning the

machine resources schedule.

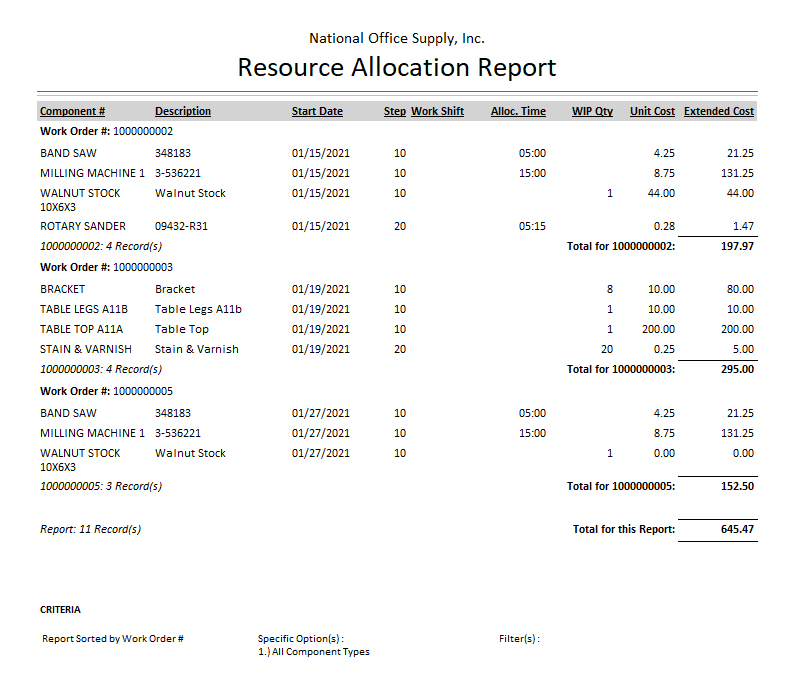

Resource Allocation Report The Resource Allocation Report provides information on inventory, labor, and machine components that are allocated or reserved for the work orders that are posted to work-in-process. Specifically, this report displays the work order numbers, work-in-process numbers, component numbers and descriptions, start dates, manufacturing step level, work shifts, allocated time, component work-in-process quantities, unit costs, and extended costs pertaining to the components that have been allocated for the work orders in process. This report can be used as reference in identifying the cost of each component in each work order that is in process. It can also help in determining the components' work-in-process quantities and the allocated time of machine and labor resources. You can choose to generate the report showing only the inventory components, only the machine

components, only the labor components, or all components regardless of their types.

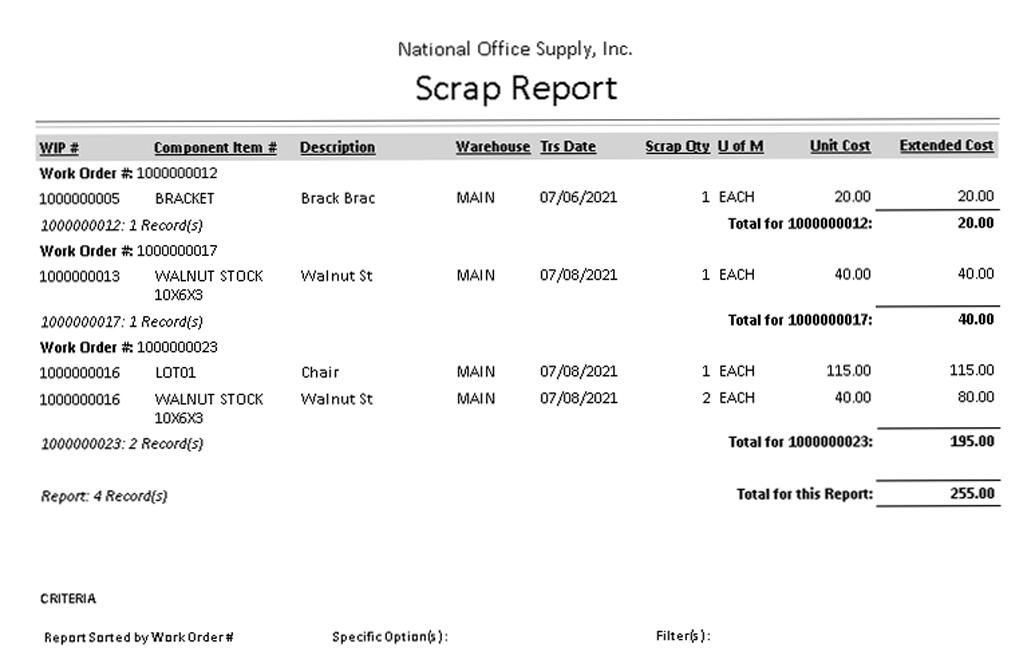

Scrap Report The Scrap Report provides information on the scrap quantities from the component items

used during the manufacturing process. The report includes work order numbers, job numbers,

component item numbers and descriptions, warehouse, finished date, scrap quantities and unit

costs, and extended costs of the scrap quantities from the component items used in completing

the job. You can use this report in identifying the scrap quantities from the component items

used in the process of completing the work order. It is also useful in monitoring and verifying

the accuracy of scrap costs.

|